- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

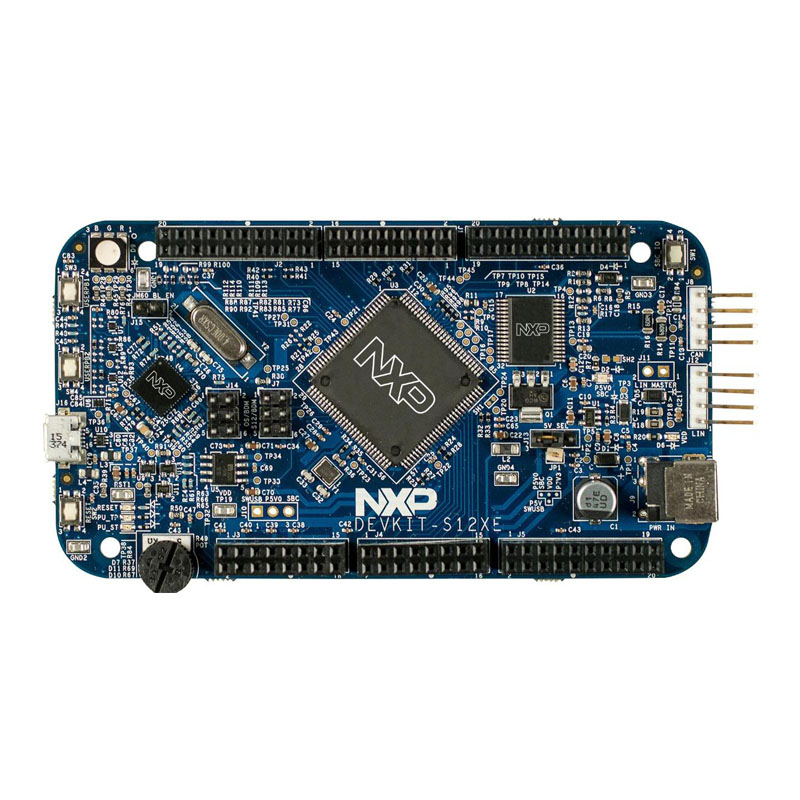

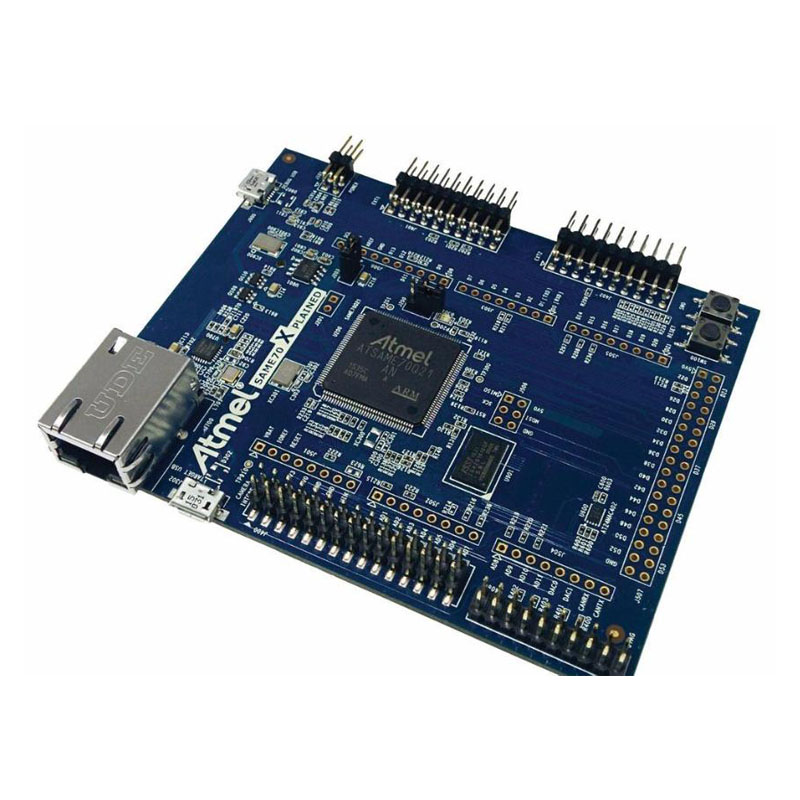

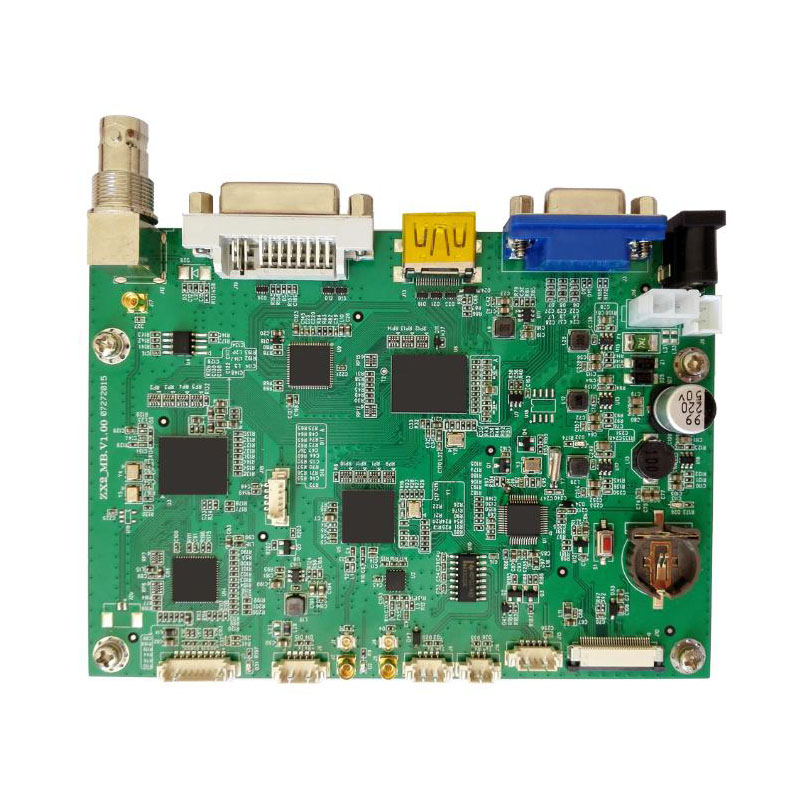

Medical ECG Monitor Control Board

A high-tech enterprise, Ningbo Hi-tech Easy Choice Technology Co., Ltd, specializes in designing, developing, and producing Medical ECG monitor control boards. Leveraging our strong credibility and top-notch service, we have established enduring collaborations with numerous large enterprises, government departments, and a broad user base. Our expertise spans intelligent electronic control board development, mechanical and electrical control product design, single-chip microcomputer development, circuit design, and comprehensive after-production testing services. Whether you provide detailed functional requirements or a mere concept, we can tailor the product's control circuit to meet your specifications and realize your desired functionalities. Bolstered by our robust research and development capabilities, an impeccable supplier system, and strict quality control measures, we seamlessly execute electronic product project design, component selection, and procurement, SMT paste processing, post-welding assembly, function testing, aging, and other integrated services, ensuring impeccable results.

Send Inquiry

YCTECH industrial product control board development includes industrial control board software design, software upgrade, schematic diagram design, PCB design, PCB production and PCBA processing located in the east coast of China. Our company designs, develops and manufactures medical ECG monitor control board. In traditional medical equipment, monitoring heart rate and heart activity is accomplished by measuring electrophysiological signals and an electrocardiogram (ECG), which involves attaching electrodes to the body to measure signals of electrical activity induced in heart tissue. The common equipment uses the electrocardiogram machine of the hospital, the dynamic electrocardiograph Holter of the long-term monitoring and so on. At present, the mainstream dynamic ECG monitoring mainly adopts two signal collection technologies of ECG and PPG. To put it simply, ECG monitoring is the electrode-type electrocardiogram monitoring technology of traditional hospitals, while PPG is LED optical monitoring technology.

PPG technology based on optical monitoring is an optical technology that can obtain cardiac function information without measuring bioelectrical signals. The basic principle is that as the heart beats, there will be pressure waves transmitted through the blood vessels. This wave will slightly change the diameter of the blood vessels. PPG monitoring uses this change to obtain the changes of the heart every time it beats. PPG is mainly used to measure blood oxygen saturation (SpO2), so it can obtain the heart rate (ie heartbeat) data of the subject in a simple way.

Electrode-based ECG monitoring technology is detected by bioelectricity, and the potential transmission of the heart can be detected by using electrodes attached to the surface of the human skin. In each cardiac cycle, the heart is excited successively by the pacemaker, the atrium, and the ventricle, accompanied by changes in the action potentials of countless myocardial cells. These bioelectric changes are called ECG. By capturing bioelectric signals and then digitally processing them, they are transformed into After digital signal processing, it can output accurate and detailed heart health information.

In comparison: the PPG technology based on optical monitoring is simpler and lower in cost, but the accuracy of the data obtained is not high and only the heartbeat value is obtained. However, the electrode-based ECG monitoring technology is more complicated, and the obtained signal is more accurate and includes the whole cycle of the heart, including the PQRST wave group, so the cost is also higher. For smart wearable ECG monitoring, if you want to obtain high-precision ECG signals, a high-performance ECG dedicated chip is essential. Due to the high technical threshold, this high-precision chip is currently mainly used by foreign TI, Provided by companies such as ADI, domestic chips have a long way to go.

TI's ECG-specific chips include ADS129X series, including ADS1291 and ADS1292 for wearable applications. The ADS129X series chip has a built-in 24-bit ADC, which has high signal accuracy, but the disadvantages of application in wearable occasions are: the package size of this chip is large, the power consumption is large, and there are relatively many peripheral components. In addition, the performance of this chip in ECG collection using metal electrodes is average, and the use of metal electrodes in wearable applications is inevitable. Another major problem with this series of chips is that the cost unit price is relatively high, especially in the context of core shortage, the supply is in short supply and the price remains high.

ADS's ECG-specific chips include ADAS1000 and AD8232, of which AD8232 is oriented to wearable applications, while ADAS1000 is more used for high-end medical equipment. ADAS1000 has a signal quality comparable to that of ADS129X, but more problems include higher power consumption, more complex peripherals and high chip prices. AD8232 is more suitable for wearable applications in terms of power consumption and size. Compared with the ADS129X series, the signal quality is quite different. Also in the application performance of metal dry electrodes, a better algorithm is also required. To use metal electrodes in wearable application scenarios, the signal accuracy is average and there is distortion, but if only to obtain accurate heart rate signals, this chip is nothing more than completely satisfactory.